Oil Price Projections To 2024

In 2021, the Brent spot price is expected to average $47.07 per barrel and the WTI spot price to average…

EPCs (Engineering Procurement and Construction firms) make huge IT investments and work largely in the information space. With the volume of digitally stored data involved with most projects, information management is a necessary and critical competency.

New documents and data being input into the systems must be properly categorized and managed, such that it can flow out to the end user plant operations on turnover.

Less time is available to verify and interpret data received, so the suppliers are being asked (forced?) to pre-process information to suit the EPC input requirements.

The EPC is also faced with the responsibility to ensure equipment is properly procured and properly manufactured. Specifics of the contract between the EPC and end user may impact how the procured material is managed. Schedule factors can put a very high importance on receiving vendor data as the project moves into the critical start up stages.

At that point, receipt of vendor data can easily be on the project critical path, jeopardizing EPC performance. By ensuring a careful review of supplier data at critical check points, the EPCs ensure mistakes are not made. Of course, the validation and checking of processes drive up the volume of documentation required especially in terms of drawings, testing and traceability.

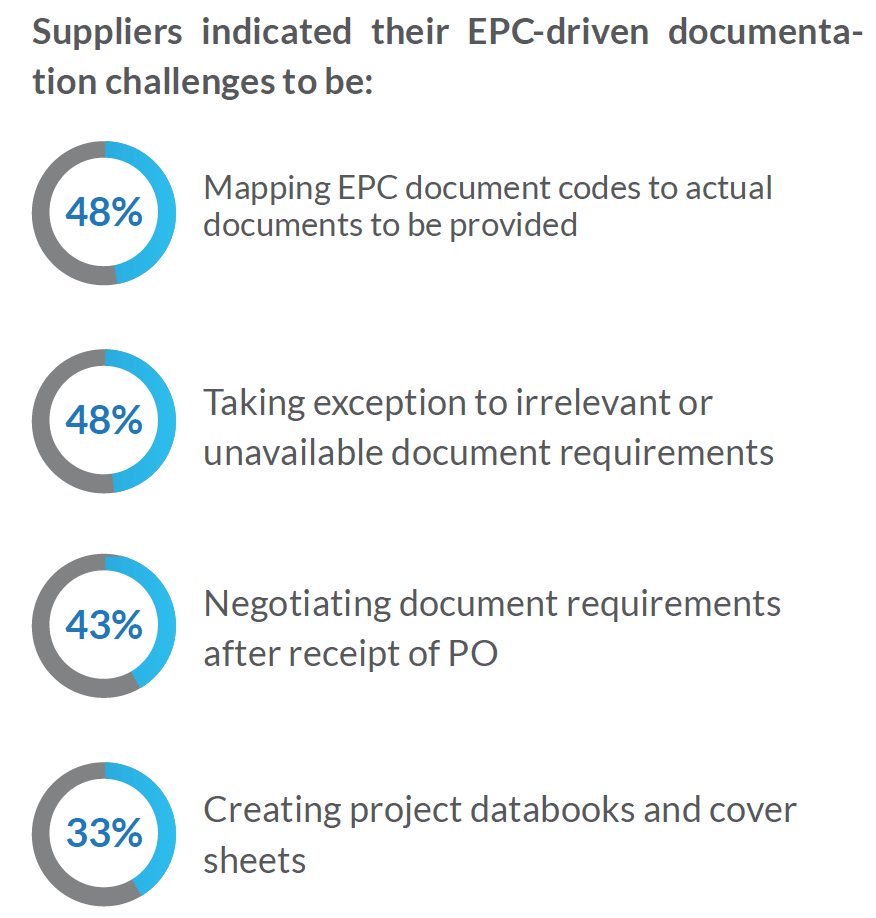

Our research has showed us that suppliers feel that their most pressing issues dealing with their EPC customers are the following:

This is the percentage of supplier respondents who chose this as one of their top three concerns.

So the biggest concerns relate to 3 items provided by the EPCs at the beginning of projects to the suppliers and 1 item (databooks) that suppliers provide to the EPCs at the end of projects.

Check out our free document control survey to learn more about how suppliers of process equipment and their EPC customers can work together better.

DocBoss is the only true document control system for

suppliers. Book a quick demo to see how we help process

equipment suppliers make more profit with less pain.