How Do You Locate Your Files?

Last summer we published a post showing that 1/3 of US and UK workers spend 5-25 minutes searching each time…

The global financial slowdown and continued depression of oil prices has reduced the number of projects that many companies are working on and thus reduced their profitability and need for staff. The difficulty of winning new projects – which are often few and far between – is also an ongoing concern.

Similarly, the need to keep your existing customers happy is paramount to ensure that you are the preferred vendor of choice when they have new projects to bid on.

EPCs make huge IT investments and work largely in the information space. With the volume of digitally stored data involved with most projects, information management is a necessary and critical competency. New documents and data being input into the systems must be properly categorized and managed, such that it can flow out to the end user plant operations on turnover. Less time is available to verify and interpret data received, so the suppliers are being asked (forced?) to pre-process information to suit the EPC input requirements.

Do you help your EPC customers with their documentation challenges?

Do you help your EPC customers with their documentation challenges?

The EPC is also faced with the responsibility to ensure equipment is properly procured and properly manufactured. Specifics of the contract between the EPC and end user may impact how the procured material is managed. Schedule factors can put a very high importance on receiving vendor data as the project moves into the critical start up stages.

At that point, receipt of vendor data can easily be on the project critical path, jeopardizing EPC performance. By ensuring a careful review of supplier data at critical check points, the EPCs ensure mistakes are not made. Of course, the validation and checking of processes drive up the volume of documentation required especially in terms of drawings, testing and traceability.

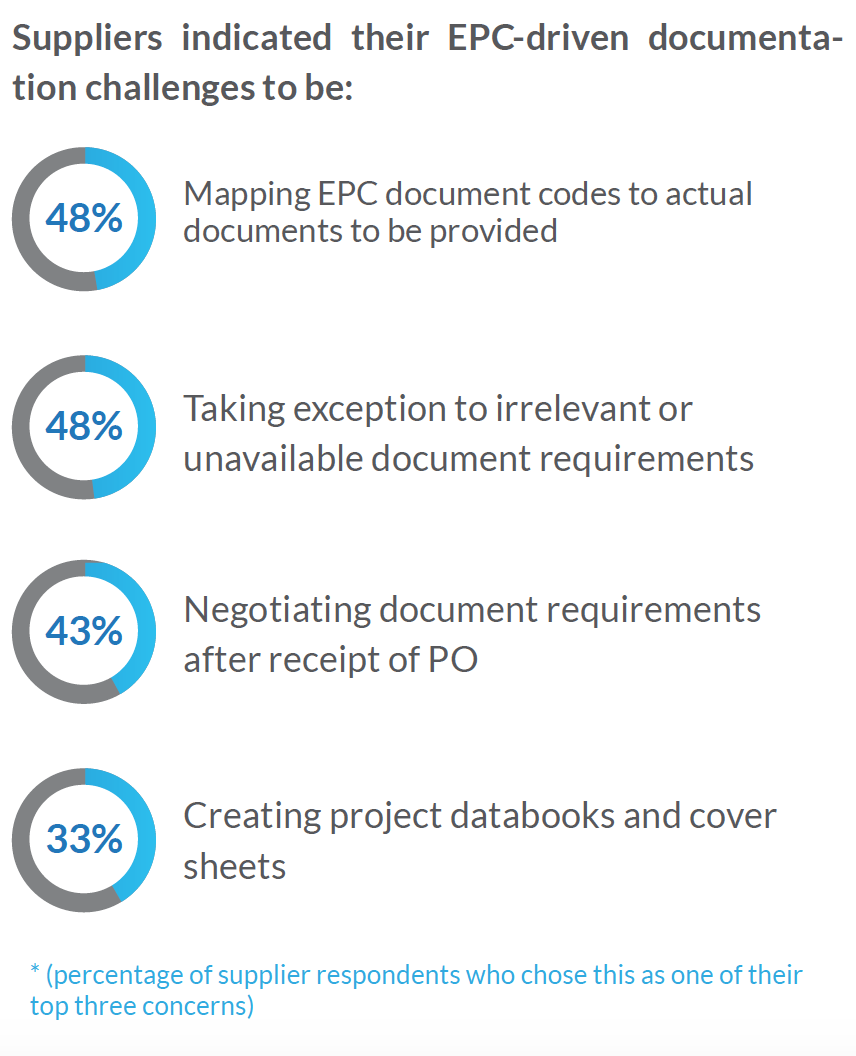

These two components lead both to an explosion in the quantity and complexity of documentation as well as the work required to submit the documentation packages.

Generally, suppliers understand these requirements and accept them as part of the supply. The frustration (and additional cost) arrives when each and every minor mistake/variation trigger the document rejection / resubmission process. A lack of empowerment at the document control function leads to frustration in the supplier community. Further, once a working relationship is established, the high turnover within the EPC document control function forces suppliers to revisit every hard won concession agreed by their previous contact.

Do you make it easy for your EPC customers to want to continue doing business with you?

How can you separate yourselves from your competitors and make EPCs want to prefer to deal with you, and not them?

If you’d like to learn more, here is a related article we’ve written that discusses how DocBoss can solve many of your documentation concerns: 10 Common Document Control Problems That DocBoss Addresses

DocBoss is the only true document control system for

suppliers. Book a quick demo to see how we help process

equipment suppliers make more profit with less pain.